Outputs

Publications

Papers in international journals

[1] P.H. Presumido, R. Montes, J.B. Quintana, R. Rodil, M. Feliciano, G. Li Puma, A.I. Gomes, V.J.P Vilar, Ozone membrane contactor to intensify gas/liquid mass transfer and contaminants of emerging concern oxidation, Journal of Environmental Chemical Engineering, 10 (2022) 108671. https://doi.org/10.1016/j.jece.2022.108671

[2] L. Vazquez, L.M.M.T. Gomes, P.H. Presumido, D.G.D. Rocca, R.F.P.M. Moreira, T. Dagnac, M. Llompart, A.I. Gomes, V.J.P. Vilar, Tubular membrane photoreactor for the tertiary treatment of urban wastewater towards antibiotics removal: application of different photocatalyst/oxidant combinations and ozonation, Journal of Environmental Chemical Engineering, 11 (3) (2023) 109766. https://doi.org/10.1016/j.jece.2023.109766

[3] P.H. Presumido, S. Ribeirinho-Soares, R. Montes, J.B. Quintana, R. Rodil, M. Ribeiro, T. Neuparth, M.M. Santos, M. Feliciano, O.C. Nunes, A.I. Gomes, V.J.P Vilar, Ozone membrane contactor for tertiary treatment of urban wastewater: chemical, microbial and toxicological assessment, Science of the Total Environment, 892 (2023) 164492. https://doi.org/10.1016/j.scitotenv.2023.164492

[4] M. Mestriner Pituco, P.H. Marrocos de Oliveira, R.J. Santos, M.M. Dias, J.C.B. Lopes, F.C. Moreira, V.J.P. Vilar, NETmix technology as ozone gas injection system: assessment of the gas-liquid mass transfer, Chemical Engineering and Processing: Process Intensification, 194 (2023) 109566. https://doi.org/10.1016/j.cep.2023.109566

[5] I.S. Fernandes, M.S.C.A. Brito, Y.A. Manrique, M.M. Dias, J.C.B. Lopes, R.J. Santos, Experimental and numerical characterisation of two-phase flow in NETmix reactors, Chemical Engineering & Processing: Process Intensification, 194 (2023) 109580. https://doi.org/10.1016/j.cep.2023.109580

[6] P.H. Marrocos, I.S. Fernandes, M.M. Pituco, J.C.B. Lopes, M.M. Dias, R.J. Santos, V.J.P. Vilar, CFD and lower order mechanistic models for gas-liquid flow in NETmix: pressure drop and gas hold-up, Chemical Engineering Science, 284 (2024) 119478. https://doi.org/10.1016/j.ces.2023.119478

[7] M.A. Prada-Vásquez, M.M. Pituco, M.P. Caixeta, S.A. Cardona Gallo, A.M. Botero-Coy, F. Hernandez, R.A. Torres-Palma, V.J.P. Vilar, Ozonation using a stainless-steel membrane contactor: gas/liquid mass transfer and pharmaceuticals removal from secondary-treated municipal wastewater, Chemosphere, 349 (2024) 140888. https://doi.org/10.1016/j.chemosphere.2023.140888

[8] P.H. Marrocos, I.S. Fernandes, M.M. Pituco, J.C.B. Lopes, M.M. Dias, R.J. Santos, V.J.P. Vilar, Evaluation of NETmix geometrical properties on gas-liquid mass transfer performance, Journal of Environmental Chemical Engineering, 12 (2024) 113771. https://doi.org/10.1016/j.jece.2024.113771

[9] I.S. Fernandes, M.M. Dias, J.C.B. Lopes, R.J. Santos, Simulation of two-phase flow in network mixers using periodic boundary conditions, Chemical Engineering Science (2024) 120661. https://doi.org/10.1016/j.ces.2024.120661

[10] M.M. Pituco, P.H. Marrocos, S. Méndez, R. Montes, R. Rodil, F.C. Moreira, V.J.P. Vilar, Ozone injection system based on NETmix technology for quaternary treatment of urban wastewater, Journal of Environmental Chemical Engineering, 13 (2025) 115465. https://doi.org/10.1016/j.jece.2025.115465

[11] M.P. Caixeta, P.H. Marrocos, I.S. Fernandes, V.J.P. Vilar, R.J. Santos, A novel Euler-Lagrange approach to simulate gas-liquid mass transfer coefficient (![]() ) in bubbly flow regimes, Chemical Engineering Science, under review (2025).

) in bubbly flow regimes, Chemical Engineering Science, under review (2025).

[12] M.M. Pituco, P.H. Marrocos, R. Montes, R. Rodil, J.B. Quintana, F.C. Moreira, V.J.P. Vilar, Sidestream ozone injection system based on the NETmix technology for pre-oxidation of drinking water, Water Research, under preparation (2025).

[13] L.J.R. Cullen, P.H. Marrocos, R.J. Santos, V.J.P. Vilar, Decoupled CFD modelling approach for operation and design optimisation of a pilot-scale sidestream contacting system for ozone water treatment, Chemical Engineering Science, under preparation (2025).

[14] I. Rodrigues, V.J.P. Vilar, A. Ferreira, A comprehensive review of O2/O3 gas separation, Chemical Engineering Journal, under preparation (2025).

[15] I. Rodrigues, V.J.P. Vilar, A. Ferreira, PDMS membrane for O2/O3 gas separation using a spiral wound module, Chemical Engineering Journal, under preparation (2025).

[16] I. Rodrigues, T.M. Mata, V.J.P. Vilar, A.F.P. Ferreira, A.A. Martins, A comprehensive life cycle assessment and costing of ozone generation systems with O2/O3 separation and oxygen recovery, Journal of Environmental Chemical Engineering, under preparation (2025).

[17] P.H. Marrocos, I.S. Fernandes, R.J. Santos, V.J.P. Vilar, A stochastic surrogate mathematical framework to describe the distribution of species in NETmix static mixers, Chemical Engineering Journal, under preparation (2025).

[18] M.P. Caixeta, P.H. Marrocos, V.J.P. Vilar, R.J. Santos, Multi-membrane module for gas-liquid contact: proposal of a scale-up methodology for ozone side-stream injection systems, Chemical Engineering Journal, under preparation (2025).

[19] C. Velhas, T. Mata, P. Marrocos, S. Almeida, S. Costa, V. Vilar, A. Martins, Sustainability assessment of sidestream ozone injection systems for water treatment: Venturi injector vs NETmix static mixer, Chemical Engineering Journal, under preparation (2025).

[20] C.S. Santos, K. Rodrigues, P.H. Marrocos, R. Montes, R. Rodil, J. B. Quintana, A. I. Gomes, V.J.P. Vilar, Integration of membrane bioreactor with ozonation for the quaternary treatment of urban wastewaters, Chemical Engineering Journal, under preparation (2025).

Papers in national journals

Communications

Communications in international meetings

[2] M.M. Pituco, P.H. Marrocos, I.S Fernandes, M.M Dias, R.J Santos, F. Moreira, J.C.B. Lopes, V.J.P. Vilar, Gas/Liquid mass transfer in the NETmix reactor: Experimental data vs CFD modelling, in 12th Micropol & Ecohazard Conference, Santiago de Compostela, Spain, 6-10th June, 2022.

[3] P.H. Presumido, R. Montes, R. Rodil, J.B. Quintana, M. Feliciano, A.I. Gomes, V.J.P. Vilar, Ozone mass transfer in a tubular porous borosilicate membrane contactor for CECs removal, in 12th Micropol & Ecohazard Conference, Santiago de Compostela, Spain, 6-10th June, 2022.

[4] P.H. Presumido, S. Ribeirinho-Soares, R. Montes, R. Rodil, J. B. Quintana, M. Feliciano, O. C. Nunes, A. I. Gomes, V. J. P. Vilar, Innovative ozone membrane contactor for tertiary treatment of urban wastewater: disinfection and CECs removal, in 12th Micropol & Ecohazard Conference, Santiago de Compostela, Spain, 6-10th June, 2022.

[5] M.M. Pituco, M.M. Sómer, R. Montes, R. Rodil, J.B. Quintana, F.C. Moreira, V.J.P. Vilar, NETmix technology as ozone gas injection system for tertiary treatment of urban wastewater, in 5th Iberoamerican Conference on Advanced Oxidation Technologies (V CIPOA), Cusco, Peru, 7-11th November, 2022.

[6] M.A. Prada, P.H. Presumido, M.M. Pituco, M.P. Caixeta, S.A. Cardona Gallo, R.A. Torres Palma, V.J.P. Vilar, Evaluation of ozone mass transfer in a tubular porous stainless steel membrane contactor, in 5th Iberoamerican Conference on Advanced Oxidation Technologies (V CIPOA), Cusco, Peru, 7-11th November, 2022.

[7] M.A. Prada, P.H. Presumido, M.M. Pituco, A.I. Gomes, S.A. Cardona Gallo, A.M. Botero-Coy, F. Hernandez, R.A. Torres Palma, V.J.P. Vilar, A novel ozone membrane contactor for the removal of CECs from secondary effluent of municipal wastewater and reverse osmosis concentrate, in 5th Iberoamerican Conference on Advanced Oxidation Technologies (V CIPOA), Cusco, Peru, 7-11th November, 2022.

[8] P.H. Marrocos, I.S. Fernandes, M.M. Pituco, R.J. Santos, V.J.P. Vilar, Gas-Liquid pressure drop of downward flows in NETmix static mixer: Experimental validation of computational fluid dynamics model, in IOA Conference & Exhibition, EA3G2022, Toulouse, France, 28-30th November, 2022.

[9] P.H. Marrocos, I.S. Fernandes, M.M. Pituco, J.C.B. Lopes, R.J. Santos, V.J.P. Vilar, Reduced-order modelling approach based on computational fluid dynamics to predict gas hold-up in micro/meso structured static mixers, in IOA Conference & Exhibition, EA3G2022, Toulouse, France, 28-30th November, 2022.

[10] M.M. Pituco, P.H. Marrocos, M.M. Dias, J.C.B Lopes, R.J. Santos, F. Moreira, V.J.P. Vilar, NETmix technology as ozone gas injection system: Assessment of the gas-liquid mass transfer, in IOA Conference & Exhibition, EA3G2022, Toulouse, France, 28-30th November, 2022.

[11] V.J.P. Vilar, I. Rodrigues, P.H. Marrocos, M.M. Pituco, F. Moreira, A.F.P. Ferreira, R.J. Santos, Cutting-edge ozone-technology for water treatment, in IOA World Congress & Exhibition, Milan, Italy, 2-7 July, 2023.

[12] P.H. Marrocos, L. Silva, M.M. Pituco, I.S. Fernandes, R.J.N. Santos, V.J.P. Vilar, Assessment of the effect of channel length on the gas-liquid mass transfer: enhancing the NETmix technology for ozonation, in MIXING 17, Porto, Portugal, 2-5 July, 2023.

[13] V.J.P. Vilar, Quaternary treatment of secondary municipal wastewaters targeting CECs removal: nanofiltration vs ozonation, in 2024 IWA Micropol and Ecohazard Conference, Taipei, Taiwan, 16-20 June, 2024.

[14] V.J.P. Vilar, M.M. Pituco, P. Marrocos, F. Moreira, Sidestream ozone injection system based on NETmix technology for water treatment, in 6th Iberoamerican Conference on Advanced Oxidation Technologies (VI CIPOA), Florianópolis, Brazil, 7-11 October 2024.

[15] I. Rodrigues, A.E. Rodrigues, V.J.P. Vilar, A.F.P. Ferreira, PDMS Membrane for O2/O3 Gas Separation Using a Spiral Wound Module, in AIChE Annual Meeting, San Diego, USA, 27-31 October, 2024.

[16] L. Cullen, P. Marrocos, R. Santos, V. Vilar, Design of an ozone side stream injection scheme: assessment of the influence of nozzle length on mixing efficiency, in Winter School on Contaminants of Emerging Concern (CECs) and Disinfection By-Products (DBPs): Occurrence, Impact and Elimination, Vila Nova de Gaia, Portugal, 25-26 November, 2024.

[17] P. Marrocos, B. Dias, R. Santos, V. Vilar, Design of a contact/reaction tank for ozone sidestream injection systems using computational fluid dynamics, in Winter School on Contaminants of Emerging Concern (CECs) and Disinfection By-Products (DBPs): Occurrence, Impact and Elimination, Vila Nova de Gaia, Portugal, 25-26 November, 2024.

[18] K. Rodrigues, P. Marrocos, M. Pituco, C. Santos, A. Narcizo, S. Pires, F. Moreira, V. Vilar, Cutting-edge ozone technology for water treatment, in Winter School on Contaminants of Emerging Concern (CECs) and Disinfection By-Products (DBPs): Occurrence, Impact and Elimination, Vila Nova de Gaia, Portugal, 25-26 November, 2024.

[19] I. Rodrigues, A.E. Rodrigues, V. Vilar, A.F.P. Ferreira, PDMS membrane for O2/O3 gas separation using a spiral wound module, in Winter School on Contaminants of Emerging Concern (CECs) and Disinfection By-Products (DBPs): Occurrence, Impact and Elimination, Vila Nova de Gaia, Portugal, 25-26 November, 2024.

[20] C. Velhas, P. Marrocos, T. Mata, S. Almeida, S. Costa, V. Vilar, A. Martins, Sustainability assessment of sidestream injection systems for ozone water treatment: Venturi vs NETmix gas/liquid injectors, in Winter School on Contaminants of Emerging Concern (CECs) and Disinfection By-Products (DBPs): Occurrence, Impact and Elimination, Vila Nova de Gaia, Portugal, 25-26 November, 2024.

[21] A.R. De Olivera, F.C. Moreira, M.A. Rodrigo, V. Vilar, Recent advancements in the production of ozone by water electrolysis, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[22] C. Velhas, T. Mata, P. Marrocos, S. Almeida, S. Costa, V. Vilar, A. Martins, Sustainability assessment of sidestream ozone injection systems for water treatment: venturi injector vs static mixer, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[23] I. Rodrigues, V. Vilar, A. Ferreira, A review of O2/O3 gas separation technologies, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[24] I. Rodrigues, V. Vilar, A. Ferreira, PDMS membrane for O2/O3 gas separation using a spiral wound module, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[25] L.J.R. Cullen, P.H. Marrocos, R.J. Santos, V. Vilar, Design of an ozone sidestream injection scheme: assessment of the influence of nozzle length on mixing efficiency, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[26] L.J.R. Cullen, P.H. Marrocos, R.J. Santos, V. Vilar, Design optimisation of a flow distribution device incorporated in a sidestream injection system for ozone water treatment, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[27] M. Lima, C. Santos, M.P. Castro, R. Montes, J.B. Quintana, R. Rodil, A. Gomes, M. Rodrigo, M. Dezotti, V. Vilar, Ozone-based treatment of nanofiltration retentate from municipal secondary effluent applying a stainless-steel membrane contactor, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[28] V. Vilar, M.P. Caixeta, P H. Marrocos, R.J. Santos, Multi-membrane module for gas-liquid contact: proposal of a scale-up methodology for ozone side-stream injection systems, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[29] M.M. Pituco, P.H. Marrocos, R. Montes, R. Rodil, J.B. Quintana, F.C. Moreira, V. Vilar, Ozone injection system based on a novel micro/meso-structured static mixer for the removal of contaminants of emerging concern from secondary effluent of urban WWTP, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[30] M.M. Pituco, P.H. Marrocos, F.C. Moreira, V. Vilar, Sidestream ozone injection system based on a novel micro/meso-structured static mixer for pre-oxidation of drinking water, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[31] P.H. Marrocos, I.S. Fernandes, M.M. Pituco, J.C.B. Lopes, M.M. Dias, R.J. Santos, V. Vilar, CFD-based assessment of the interfacial area generation mechanisms of gas-liquid flows in a novel micro/meso-structured static mixer, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[32] P.H. Marrocos, I.S. Fernandes, M.M. Pituco, J.C.B. Lopes, M.M. Dias, R.J. Santos, V. Vilar, Assessment of topological characteristics of a novel micro/meso-structured static mixer on the gas-liquid mass transfer performance, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

[33] C.S. Santos, K. Rodrigues, P.H. Marrocos, A. Narcizo, R. Montes, R. Rodil, J.B. Quintana, A.I. Gomes, V. Vilar, Integration of membrane bioreactor with ozonation for the quaternary treatment of urban wastewaters, in IOA Conference & Exhibition, EA3G2024, Vila Nova de Gaia, Portugal, 27-29 November, 2024.

Communications in national meetings

[2] M.M. Pituco, R.J. Santos, M.M. Dias, F.C. Moreira, V.J.P. Vilar, Assessment of the volumetric ozone-water mass transfer coefficients in the NETmix®, in 4th Doctoral Congress in Engineering (DCE21), Symposium on Chemical and Biological Engineering, Porto, Portugal, 28-29th June, 2021.

[3] M.P. Caixeta, R.J. Santos, V.J.P. Vilar, CFD modeling and simulation of a tube-in-tube membrane reactor for ozonation towards CECs removal from municipal wastewaters, in 4th Doctoral Congress in Engineering (DCE21), Symposium on Chemical and Biological Engineering, Porto, Portugal, 28-29th June, 2021.

[4] V.J.P. Vilar, I. Rodrigues, A.E. Rodrigues, A.F.P. Ferreira, Development of functionalized membranes for O2/O3 gas separation, in International Chemical and Biological Engineering Conference (CHEMPOR), Bragança, Portugal, 12-15th September 2023.

[5] I. Rodrigues, L. Martínez-Izquierdo, C. Téllez, J. Coronas, A.E. Rodrigues, V.J.P. Vilar, A.F.P. Ferreira, Symmetric and asymmetric PDMS membranes for CO2/N2 separation using the inorganic filler ZSM-5, in International Chemical and Biological Engineering Conference (CHEMPOR), Bragança, Portugal, 12-15th September 2023.

[6] M.P. Caixeta, P.H.M. de Oliveira, R. J. Santos, V.J.P. Vilar, A novel CFD approach to calculate the ozone mass transfer coefficient (![]() ) in a tube-in-tube membrane reactor: coupling numerical and analytical modeling, in International Chemical and Biological Engineering Conference (CHEMPOR), Bragança, Portugal, 12-15th September 2023.

) in a tube-in-tube membrane reactor: coupling numerical and analytical modeling, in International Chemical and Biological Engineering Conference (CHEMPOR), Bragança, Portugal, 12-15th September 2023.

[7] V.J.P. Vilar, I. Rodrigues, P. Marrocos, M. Pituco, A. Ferreira, R. Santos, Tecnologia de ponta de ozono para tratamento de água, Encontro Nacional de Entidades Gestoras de Água e Saneamento (ENEG2023), Gondomar, Portugal, 27-30th November 2023.

Organization of workshops

[1] Workshop on Technology Transfer Opportunities in New Regulatory Frameworks, organized by AdP Valor, integrated into an event of Águas de Portugal company, Cnema-Centro Nacional de Exposições, Santarém, Portugal, 28th February, 2024.

[2] Winter School on Contaminants of Emerging Concern (CECs) and Disinfection By-Products (DBPs): Occurrence, Impact and Elimination, World of Wine (WOW), Vila Nova de Gaia, Portugal, 25-26th November, 2024.

[3] IOA Conference & Exhibition, International Conference on Ozone and Advanced Oxidation-EA3G2024, World of Wine (WOW), Vila Nova de Gaia, Portugal, 27-29th November, 2024.

[4] Workshop on Quaternary Treatment Technologies for Micropollutants Removal, Freixo WWTP, Porto, Portugal, 16th December, 2024

Advanced formation

PhD Thesis

[2] Isabel Sousa Fernandes, Multiphase flow in NETmix: mixing studies and applications, Faculty of Engineering University of Porto, 2019-2023, Scholarship from FCT: SFRH/BD/143958/2019, Supervisor: Ricardo Jorge Nogueira dos Santos, co-supervisor: José Carlos Brito Lopes, concluded on 16th November 2023.

[3] Mateus Mestriner Pituco, Intensification of ozonation processes in a novel pressurized mili-reactor for water and wastewater treatment, Faculty of Engineering University of Porto, 2020-2024, Scholarship from FCT: SFRH/BD7144673/2019, Supervisor: Vítor Jorge Pais Vilar, co-supervisor: Maria Francisca da Costa Moreira, on-going.

[4] Mateus Pereira Caixeta, CFD modeling and simulation of a tube-in-tube membrane reactor for ozonation towards CECs removal from municipal wastewaters, Faculty of Engineering University of Porto, 2020-2024, Scholarship from FCT: 2020.06681.BD, Supervisor: Ricardo Jorge Nogueira dos Santos, co-supervisor: Vítor Jorge Pais Vilar, on-going.

[5] Cristiana Andreia Vieira Gomes, Valorization and treatment of wastewater from the canning industry, Faculty of Engineering University of Porto, 2022-2026, Scholarship from FCT: 2021.05666.BD, Supervisor: Alexandre Ferreira Porfírio Ferreira, co-supervisor: Ana Mafalda Almeida Peixoto Ribeiro and Vítor Jorge Pais Vilar, on-going.

[6] Inês Magalhães Rodrigues, Ozone stream purification using customized membranes for O2/O3 separation, Faculty of Engineering University of Porto, 2022-2026, Scholarship from FCT: 2022.10784.BD, Supervisor: Alexandre Ferreira Porfirio Ferreira, co-supervisor: Vítor Jorge Pais Vilar, on-going.

[7] Paulo Henrique Marrocos de Oliveira, Cutting-edge ozone static mixer based on a micro/meso structured pressurized NETmix reactor: Experimental and CFD Modelling, Faculty of Engineering University of Porto, 2022-2026, Scholarship from FCT: 2022.10437.BD, Supervisor: Vítor Jorge Pais Vilar, co-supervisor: Ricardo Jorge Nogueira dos Santos, on-going.

Master Thesis

[2] Soraia Fortuna Pires, Tecnologia de ponta de ozono para a pré-oxidação de água para consumo humano, Master Thesis in Environmental Engineering, Faculty of Engineering University of Porto, Supervisor: Vítor Jorge Pais Vilar, co-supervisors: Maria Francisca da Costa Moreira, Ana Isabel Gomes, concluded on 10/07/2024.

[3] Catarina Bastos Velhas da Silva, Avaliação da sustentabilidade de sistemas de ozonização para tratamento de água para consumo humano: Injetor venturi vs NETmix, Master Thesis in Environmental Engineering, Faculty of Engineering University of Porto, Supervisor: António Martins (FEUP), co-supervisors: Vítor Jorge Pais Vilar (FEUP), Teresa Mata (INEGI), Sérgio Almeida (Simbiente), concluded om 12/07/2024.

[4] Nathália Garcia Duarte, CFD-based assessment of mixing and energy performance of a full-scale sidestream ozone injection system, Master Thesis in Chemical Engineering, Faculty of Engineering University of Porto, Supervisor: Vítor Jorge Pais Vilar, Co-supervisor: Ricardo Jorge Nogueira dos Santos, on-going.

[5] Bárbara de Sousa, Quaternary treatment of urban wastewaters targeting CECs and microplastics removal, Master Thesis in Environmental Engineering, Faculty of Engineering of the University of Porto, Supervisor: Vítor Jorge Pais Vilar, Co-supervisor: Ana Isabel Gomes, on-going.

Short Term Scientific Missions

[2] Inês Magalhães Rodrigues, University of Zaragoza, Chemical & Environmental Engineering Department, Nanoscience and Materials Institute of Aragón (INMA), Zaragoza, Spain, Supervised by Prof. Joaquin Coronas, from 10th January to 10th April.

[3] Maria Francisca da Costa Moreira, University of Castilla-La Mancha (UCLM), Castilla-La Mancha, Spain, Supervised by Prof. Dr. Manuel Andrés Rodrigo, from 1st to 28th February 2024.

Prototypes

Laboratory set-up for O2/O3 separation using membranes.

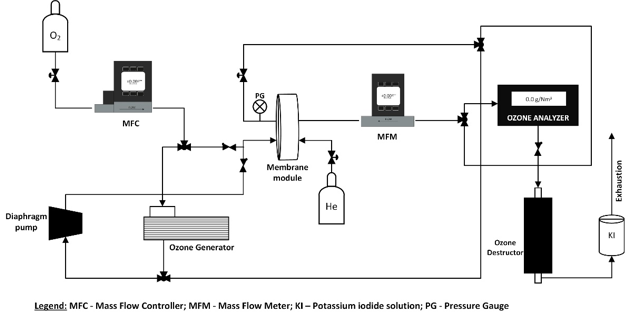

Description: The gas separation laboratory set-up consist of the following components: i) oxygen cylinder; ii) mass flow controller to regulate the flow of oxygen that is fed into the system; iii) corona discharge ozone generator; iv) diaphragm pump to compress the ozone stream up to 5 bar abs; v) membrane module made of stainless steel, incorporating the synthesized membranes (useful area of 2 cm2 or 28 cm2); vi) helium cylinder, where helium can be used as a carrier gas to decrease O3 concentration and therefore increase the partial pressure difference (driving force in a gas separation system); vii) pressure gauge to measure the pressure in the retentate stream up to 10 bar; viii) mass flow meter to measure the permeate stream flow; ix) ozone analyzer, capable of measuring ozone concentration in the feed, permeate and retentate streams; x) catalytic O3 destruction unit and O3 destroyer bottle (containing a 2% KI solution) to ensure total ozone destruction.

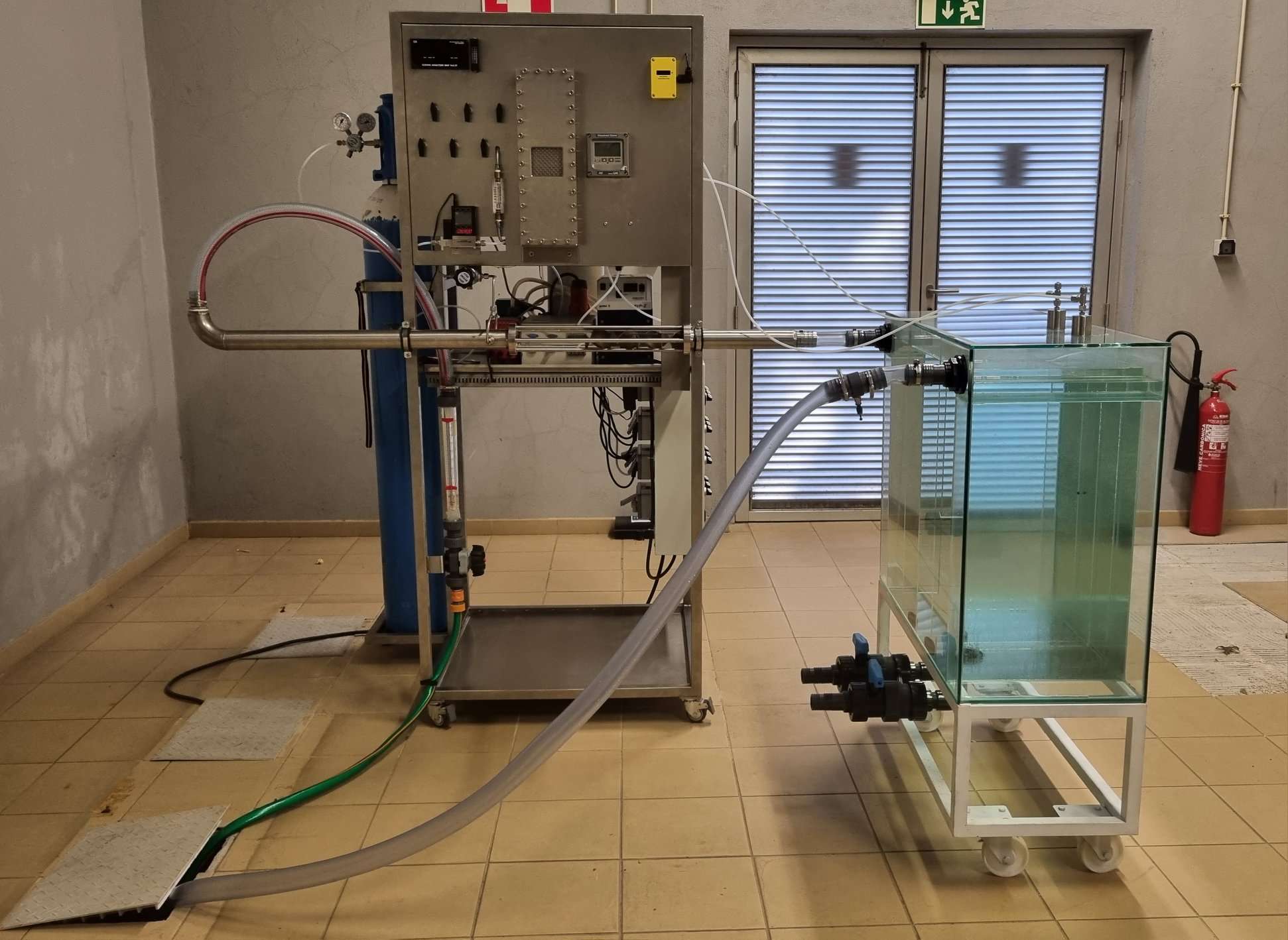

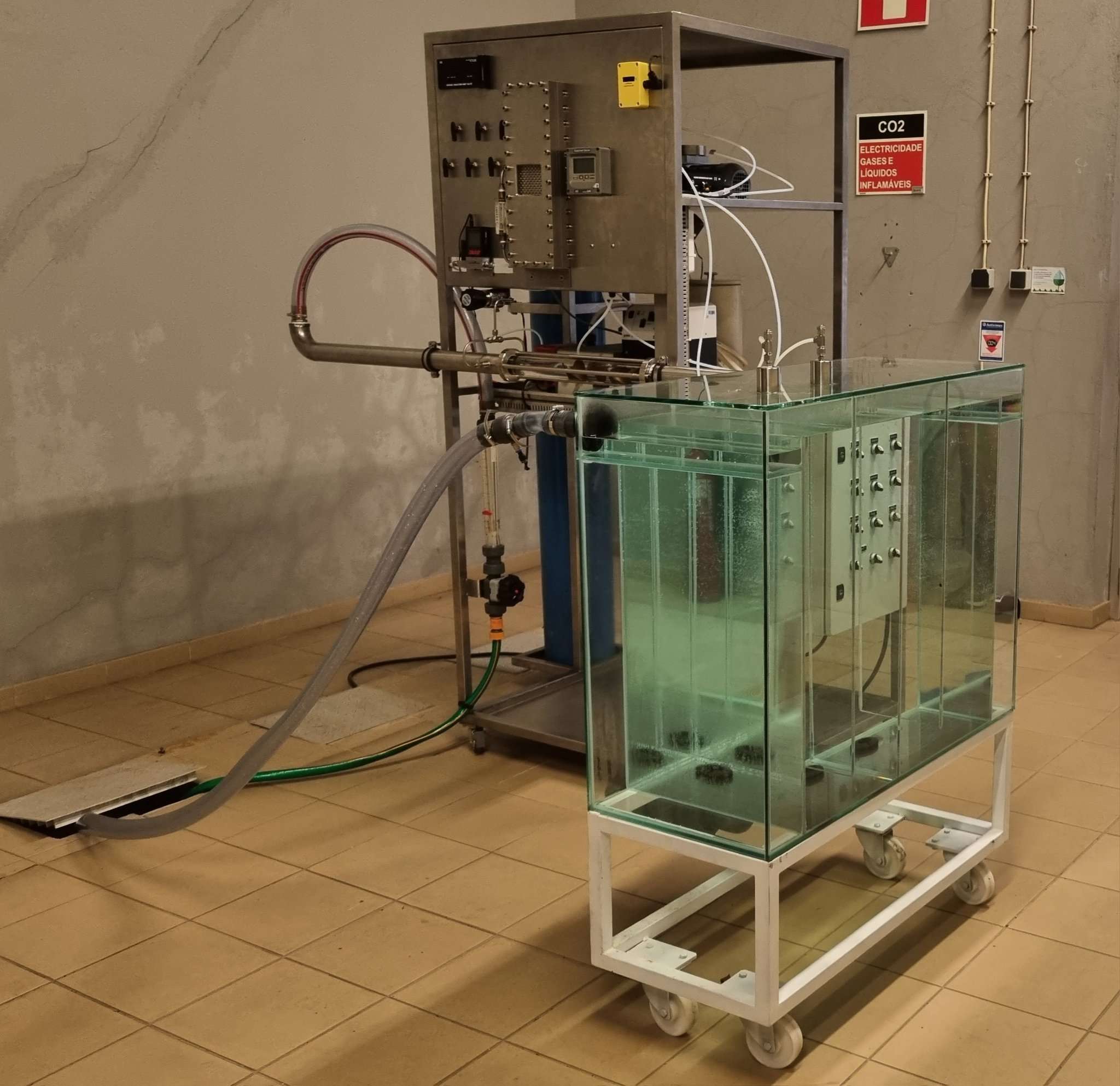

Laboratory prototype for water treatment – ozone side stream contacting train

Description:

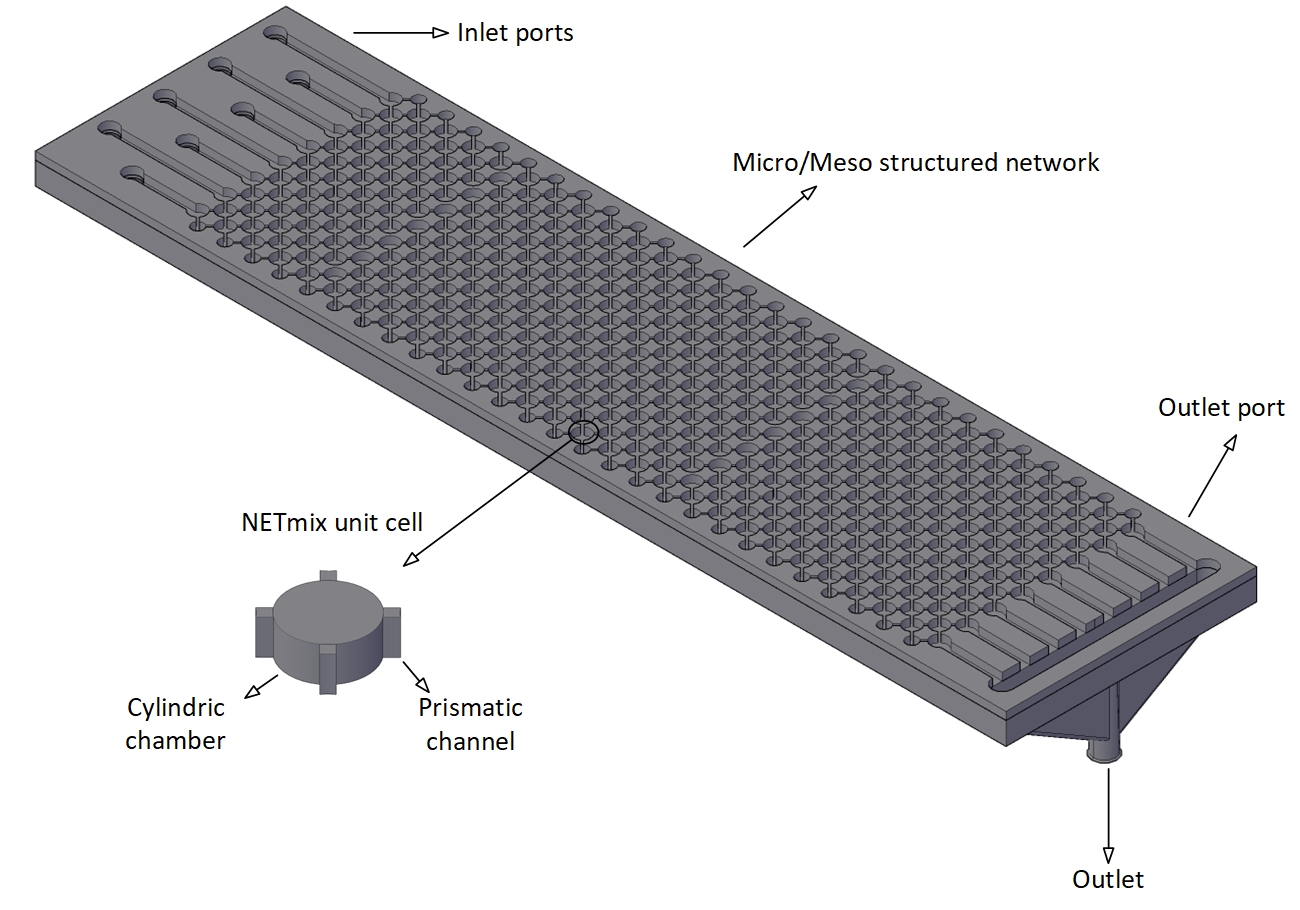

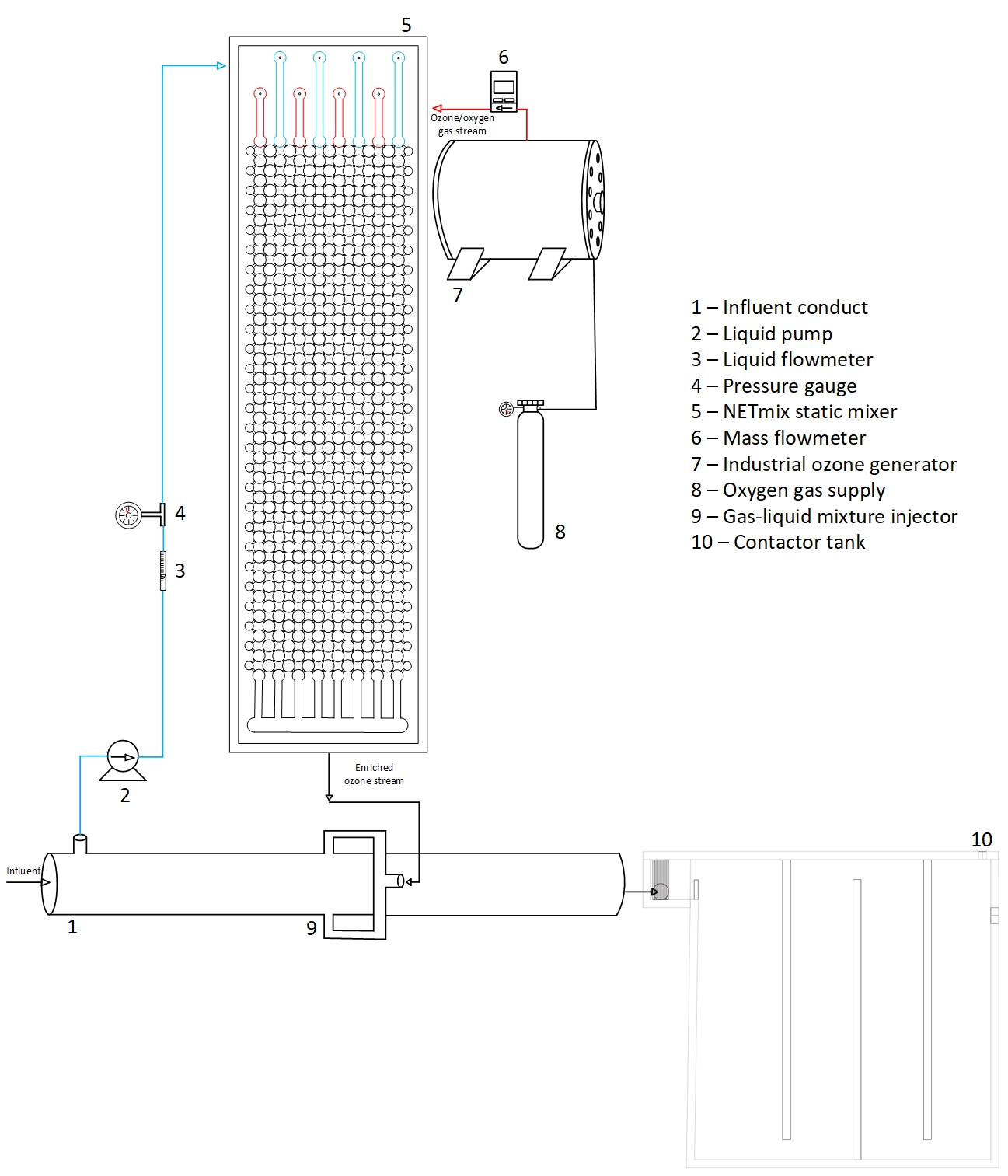

A typical sidestream ozone injection system is used (Figure 1), where a fraction of the main water flow is diverted from the pipeline (1) to the newly developed NETmix unit (5) so that the ozone gas produced from the industrial generator (7) is injected and efficiently mixed inside the NETmix static mixer.

The new NETmix unit, shown in Figure 2, comprise two injection cones for the separate distribution of the fluids at the inlet of the mixer: each cone has a circular entrance with 8.8 mm diameter, a total height of 30 mm, and an elliptical base with 8.8 mm width and 88 mm length.

The new NETmix unit, shown in Figure 2, comprise two injection cones for the separate distribution of the fluids at the inlet of the mixer: each cone has a circular entrance with 8.8 mm diameter, a total height of 30 mm, and an elliptical base with 8.8 mm width and 88 mm length.

Both the liquid phase and the gas phase are injected separately in alternate four cylindrical chambers with 6.75 mm diameter each. Thus, the two phases only interact at the micro/meso-structured network. Each of these unit cells are composed by cylindrical chambers with 6.75 mm diameter and 3 mm height interconnected to four prismatic half-channels, each at a 45º direction of the flow, with 0.5 mm length, 1 mm width and 3 mm height. Horizontally, the NETmix plate contains 8 unit cells, whereas vertically, 55 unit cells, enabling a 30.1 cm vertical distance between the first and last chambers. At the outlet, the gas-liquid mixture is collected by a cone identical to those used at the inlet. Under the NETmix plate, it was inserted a heat transfer system, whereby a fluid will pass through a zone filled with fins, responsible for the heat transfer from the plate to the passing fluid, thus, cooling the system. These fins measure 6 mm width, attaining 7.22 mm length from the two farthest points, and 6 mm height: each fin was conceived in a shape resembling a water drop, to reduce friction with the contacting fluid. The new NETmix is made of stainless steel.

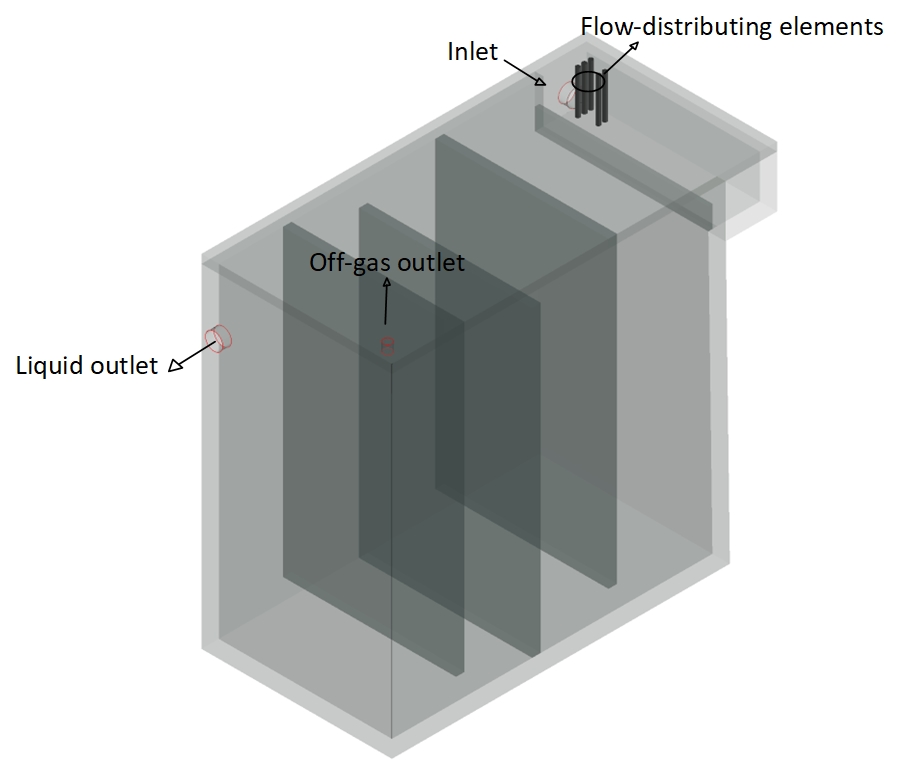

Moreover, the contactor tank, shown in Figure 3, presents a capacity of 225 dm3, being contained in a compartment with 75 cm length, 75 cm height, and 40 cm width. The tank is provided with three baffles to reduce dead volume, whereby each will have 70 cm height. In addition, it was conceived an injection chamber, responsible for the distribution and injection of the gas-liquid mixture inside the tank, with a width and height of 10 cm, and length of 40 cm. Within it, five cylinders of 1 mm diameter are placed, three at 2 cm and two at 6 cm of the inlet, respectively, with the objective of improving the distribution of the fluid flow, and a baffle measuring 5 cm height ensures that the fluid only flows through a 40 cm × 5 cm gap towards the tank. Furthermore, the contactor has one inlet and two outlets: one dedicated to the off-gas, and another to the liquid phase. The tank is made of glass, so that the flow can be easily visualized.